M W Industries Incorporated

Welcome to M W Industries Incorporated, a Houston-based manufacturer delivering high-precision metal components since 1976. Located at 2400 Farrell Road, Houston, Texas 77073, we specialize in custom and specialty washers, precision metal stamping, CNC machining, metal fabrication, fasteners, brackets, laser cutting, punch press work, and complete tool and die support. For more than four decades, OEMs and suppliers across industries have relied on our consistent quality, engineering support, and on-time performance for mission-critical parts. Call (800) 875-3510 to speak with our sales team or Request a Quote to start your project.

Why our manufacturing matter

Small components — washers, brackets, fasteners, stampings — are often overlooked until they fail. When they do, production line downtime, warranty claims, and safety risks multiply costs and damage reputations. Precision parts are the foundation for reliable assemblies across automotive, HVAC, electrical hardware, industrial equipment, and many other sectors. The right metal stamping, the correct washer geometry, and properly machined features keep assemblies aligned, reduce wear, prevent loosening, and simplify assembly automation.

M W Industries matters because we focus on these foundational elements: repeatable tolerances, material specification control, and production methods that scale from prototype to high-volume runs. Our decades of experience mean we anticipate manufacturing challenges early — from material springback in stampings to burr control on punched edges and tolerance stack in multi-component assemblies. That reduces redesign cycles and accelerates time-to-market.

Key benefits of choosing M W Industries

Proven experience since 1976

Our long history means institutional knowledge. We’ve evolved with manufacturing technologies and maintain processes that deliver consistent results.

Broad in-house capabilities

With precision stamping, CNC machining, laser cutting, punch press, and tool & die services under one roof, we reduce hand-offs, shorten lead times, and lower logistics overhead.

Custom and specialty washers expertise

We design and produce washers with specialized profiles, coatings, and material selections for applications that demand more than off-the-shelf hardware.

Tight tolerances and repeatability

Our quality systems focus on dimensional control, material traceability, and inspection protocols that support highly repeatable production.

Engineering and supply chain support

We partner early in product development to recommend cost-effective manufacturing approaches, material substitutions, and design-for-manufacture improvements.

Responsive customer service and communication

A dedicated account team ensures clarity, status visibility, and on-time delivery.

How M W Industries can help

From the first sample to long-run production, our approach is collaborative and detail-oriented. We begin with engineering discussions to understand your functional requirements, operating environment, and end-use constraints. Whether you need a specialty flat washer that resists seizing under high temperature, a stamped bracket with complex form features, or precision CNC-machined spacers, we provide manufacturing options that balance cost and performance.

Our process includes:

Design review and manufacturability feedback to reduce cost and ensure performance

Prototype and short-run capability for validation and testing

Tooling and die design in-house to preserve control and speed up iterations

Full production with process controls and inspection plans

Packaging and logistics tailored to your assembly line or distribution model

Products overview

Our products are engineered and manufactured to meet demanding specifications:

Custom and specialty washers

Flat washers, wave washers, lock washers, tab washers, shoulder washers, and other specialty geometries with custom ID/OD, thickness, material, and finish options.

Precision metal stamping parts

High-volume stampings for assemblies requiring tight tolerances, formed features, and secondary operations like tapping, bending, or staking.

CNC machined components

Turning and milling parts with precision features, threads, bores, and surface finishes from small prototypes to complex production runs.

Fasteners and brackets

Custom fasteners, clips, and brackets designed for secure assembly and repeatable performance in harsh conditions.

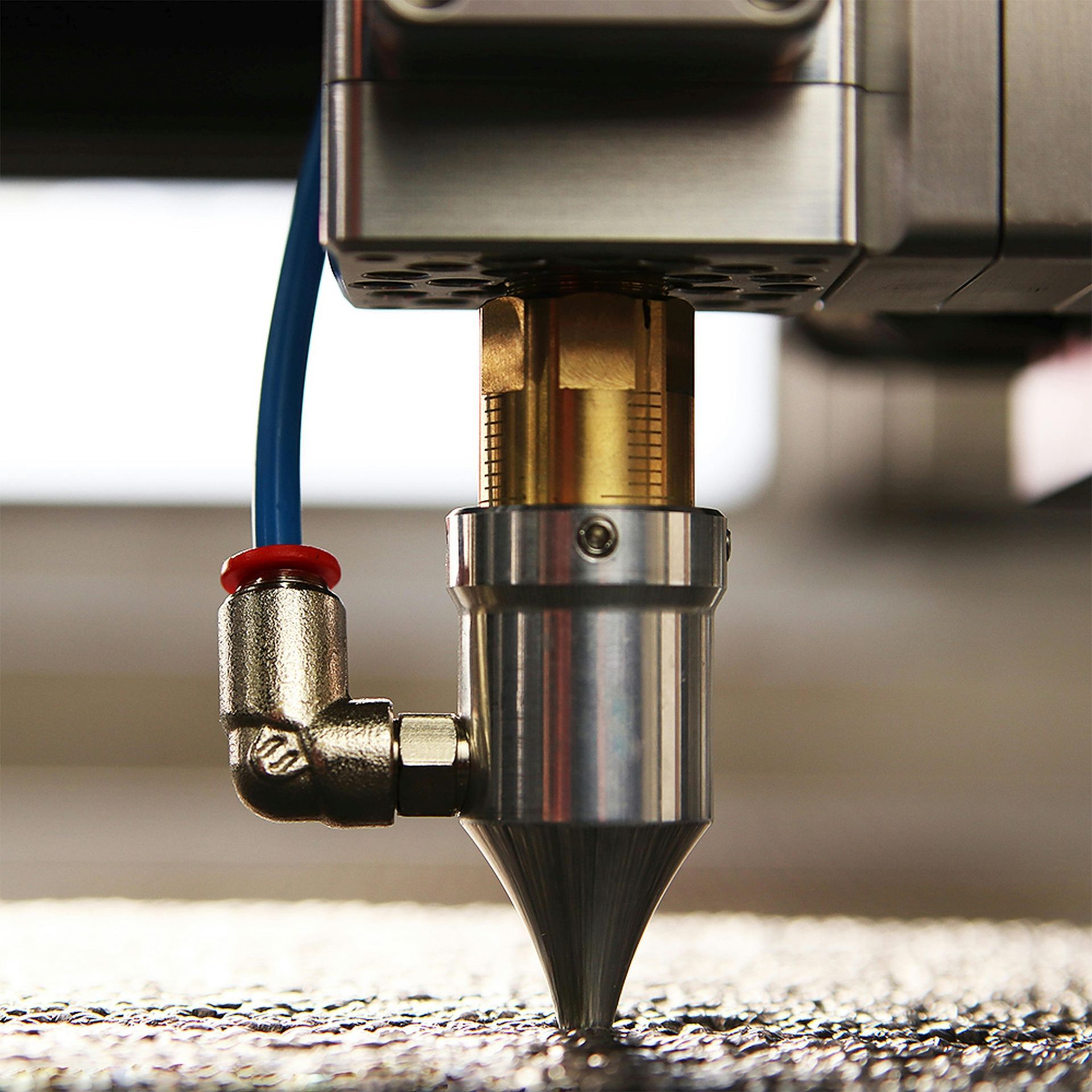

Laser cutting and punch press parts

Prototype to production sheet metal work with clean edges and consistent kerf control.

Tool & Die

In-house toolrooms design, build, and maintain dies and fixtures, reducing lead times and enabling fast response to wear or design changes.

Industries we serve

M W Industries supplies parts to a wide range of industries including:

HVAC and refrigeration

washers, spacers, mounting brackets, and fasteners designed for long service life in temperature- and moisture-variable environments.

Electrical and electronics hardware

precision stampings and washers for reliable electrical connections and mechanical support.

Industrial equipment and machinery

brackets, stampings, and machined components engineered for strength and durability.

Appliance and consumer goods

cost-effective production with quality control for repeatable consumer use.

Transportation and off-road

high-strength fasteners, washers, and stampings for assemblies exposed to vibration and harsh environments.

Quality, materials, and finishes

We work with a broad range of metals:

Carbon steels, stainless steels (300 & 400 series), brass, bronze, aluminum grades, and specialty alloys.

Surface treatments and finishes: passivation, plating (zinc, nickel), phosphate coatings, anodizing options for aluminum, and custom lubricants or anti-seize treatments on request.

Material traceability: Raw material lot control and documentation for customers with traceability requirements.

Why precision matters for washers and small parts

Washers might seem simple, but the right thickness, hardness, internal chamfer, and surface finish can be critical. A locking washer with insufficient spring force will allow loosening under vibration. A copper washer with incorrect hardness may deform and leak in sealing applications. Specialty washers for thermal or electrical isolation must control dielectric properties and conductivity. We work with designers to specify the correct geometry and metallurgy for the intended function rather than relying on standard catalog parts that may not perform.

How we support product development and cost reduction

Partnering with M W Industries early yields real benefits:

Design-for-manufacture guidance reduces part count and simplifies assembly.

Material and process options lower unit cost while preserving function.

Feeder and assembly packaging designs that speed line operations.

onsolidation of multiple stamped parts into single formed stampings where feasible.

Value analysis and continuous improvement programs to lower total cost of ownership.

Frequently asked questions (FAQs)

What minimum order quantities (MOQs) do you require?

MOQs vary by product and process. For prototyping and testing, we provide short-run samples. For high-volume stamping or low-cost per-unit targets, higher volumes are typically required to amortize tooling. Contact our sales team with your specifications and target volumes and we will propose a practical path forward.

Can you handle custom alloys and heat-treated parts?

Yes. We work with common and specialty alloys and coordinate heat-treating processes when required. We document material specifications and handling instructions to ensure traceability and performance.

Do you provide engineering support and tooling design?

Yes. Our in-house tool & die and manufacturing engineering teams help with tooling design, die maintenance, and optimizing part features for production efficiency.

What inspection and quality controls do you use?

Standard controls include incoming material inspection, dimensional inspection using calibrated gauges and CMM where necessary, statistical process control, and first article inspection upon request. We can develop custom inspection plans for critical features.

What lead times can I expect?

Lead times depend on complexity, tooling requirements, and order volume. Prototype parts can often be produced in weeks; tooling and production lead times vary. Call (800) 875-3510 to discuss scheduling for your part.

Contact

Start your next project with M W Industries. For technical questions, drawing reviews, or to request a sample:

- Address: 2400 Farrell Road, Houston, Texas 77073

- Request a Quote: Provide part drawings, material specs, annual volumes, target price, and intended applications.