Our Work M W Industries Incorporated

M W Industries Portfolio Overview

M W Industries Incorporated delivers practical manufacturing solutions that solve real-world problems. Since 1976 we have partnered with customers across HVAC, electrical hardware, industrial equipment, and related sectors to manufacture components that improve assembly robustness, reduce production costs, and meet strict performance standards. Our portfolio demonstrates versatility — from specialty washers that solve vibration issues to complex stamped brackets that integrate mounting features and fastener retention systems.

Why showing our work matters

A supplier’s work demonstrates not just what they can produce, but how they solve manufacturing and engineering problems. Case examples provide insight into process selection, innovation in tooling, and results such as reduced assembly time, improved field reliability, and cost savings achieved through design optimization. When prospective customers see concrete examples, they can better assess fit and potential for collaboration.

Selected examples of our work

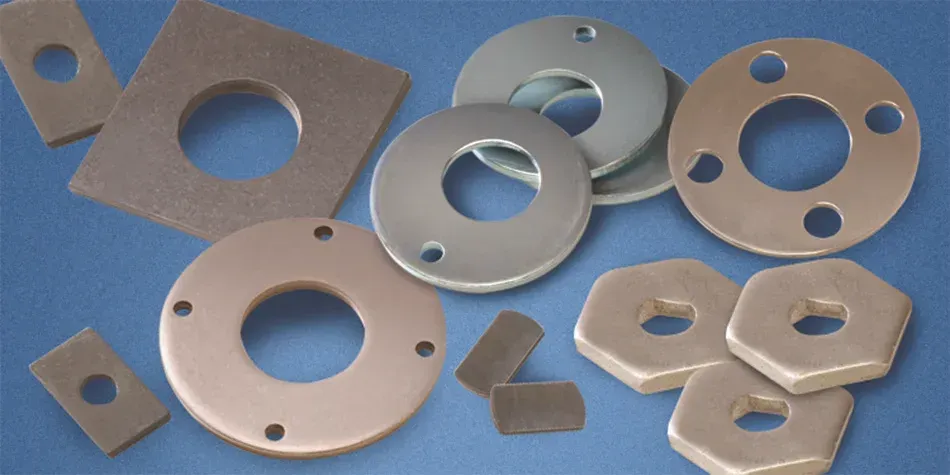

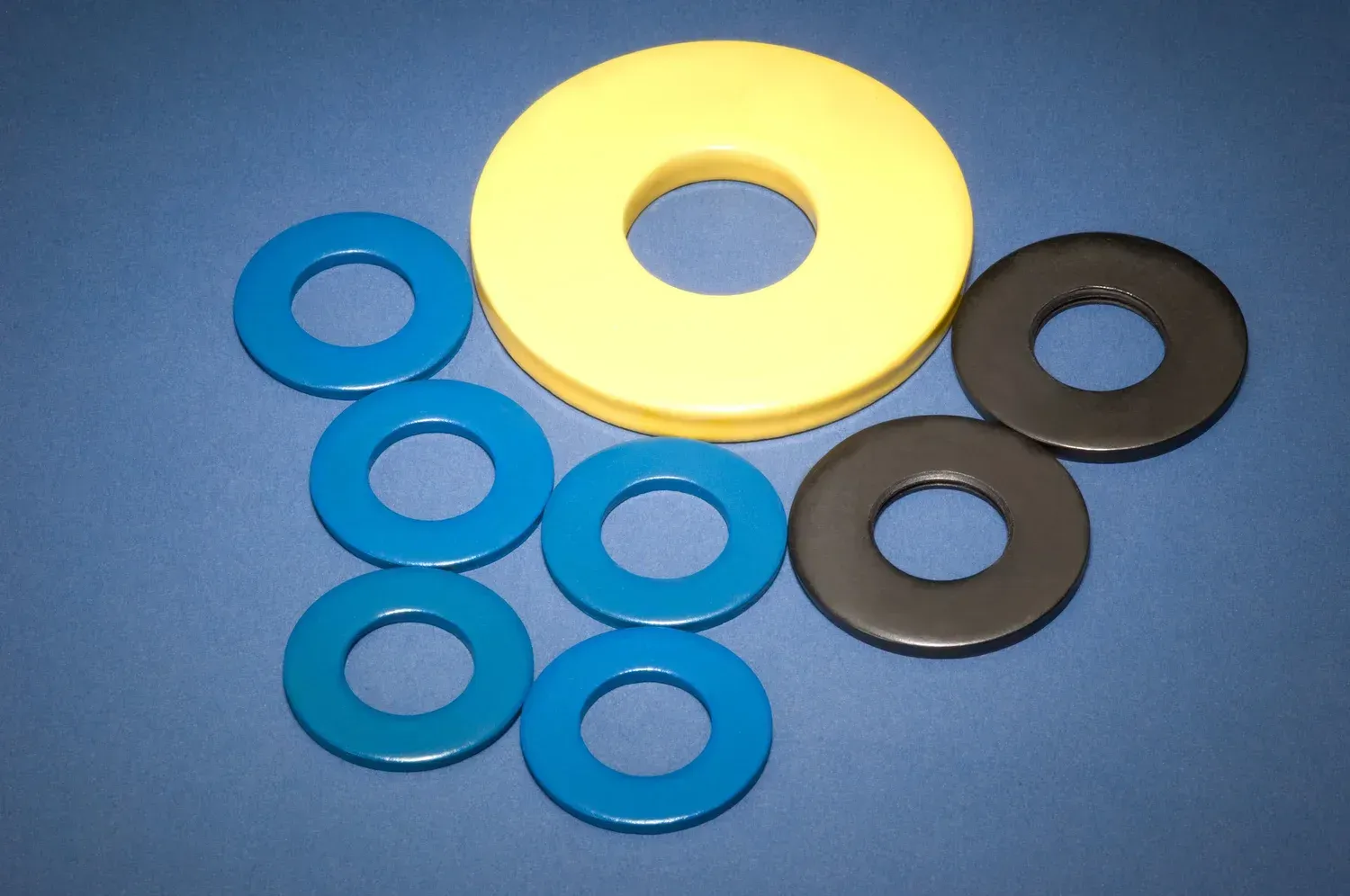

Case 1: Specialty Washer Program for Vibration Resistance (HVAC OEM)

Challenge: An HVAC OEM experienced recurring fastener loosening in compressors subject to cyclic vibration and temperature swings, causing service calls and downtime.

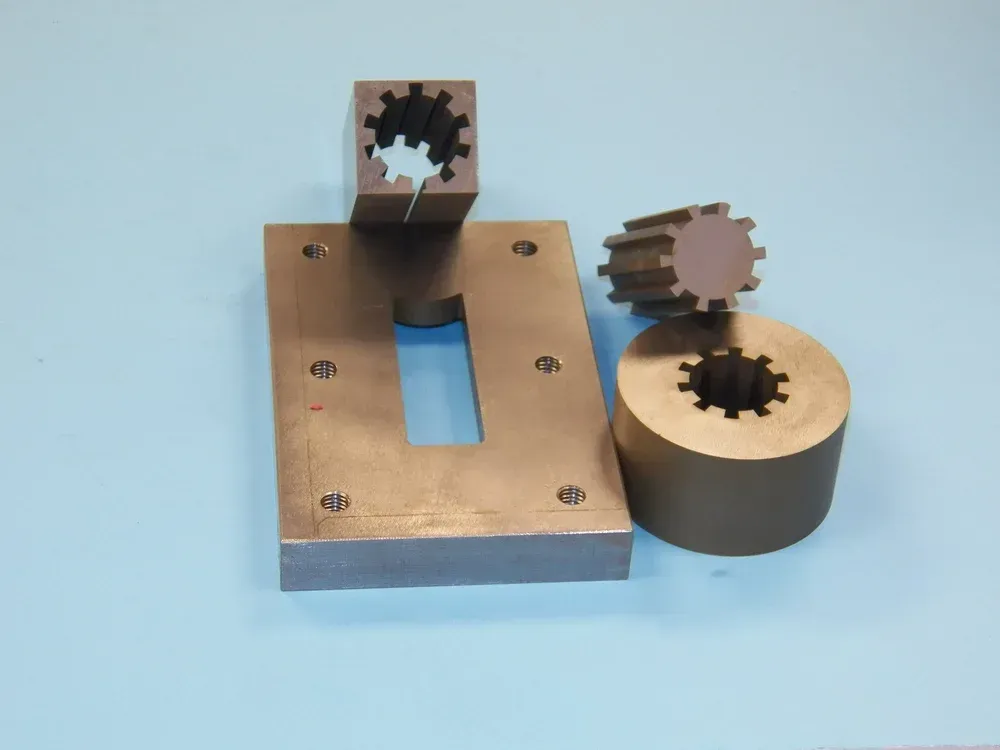

Solution: M W Industries engineered a custom serrated lock washer with altered tooth geometry and a light friction coating to increase retention. Material and heat-treat selection ensured spring properties persisted over temperature cycles.

Result: The new washer reduced field loosening incidents by over 70% in initial trials, reduced service claims, and allowed the OEM to extend maintenance intervals. The washer was introduced into production with a packaging format compatible with their automated assembly lines.

Case 2: High-Volume Precision Stampings for Electrical Enclosures

Challenge: A supplier of electrical enclosures needed a complex formed bracket with tight dimensional requirements for snap-in assembly of connectors.

Solution: We designed a progressive die with integrated coining and forming steps that controlled material flow and minimized secondary machining. The die included features to manage burr formation and controlled strip tension to maintain repeatable geometry.

Result: The stamping achieved required tolerances at high line speeds, eliminating the need for secondary machining and reducing part cost by 18% versus the customer’s prior subcontractor.

Case 3: CNC Machined Spacers for Precision Instrumentation

Challenge: A manufacturer required spacers with concentricity and straightness that exceeded capabilities of off-the-shelf parts.

Solution: M W Industries produced turned and ground spacers with tight concentricity and surface finish, including custom surface treatments for lubrication and corrosion protection.

Result: The parts met stringent dimensional requirements and improved assembly alignment, enabling improved product performance for the instrumentation manufacturer.

Case 4: Bracket Consolidation to Reduce Part Count (Industrial Equipment)

Challenge: A machinery OEM had an assembly that used three separate stamped parts to secure a subassembly, increasing assembly time and fastener inventory.

Solution: Our engineering team redesigned the feature set into a single, slightly more complex stamped and formed bracket that incorporated retention features previously provided by additional parts.

Result: The consolidation reduced assembly time, reduced inventory SKUs, simplified logistics, and lowered overall part cost while preserving structural performance.

Case 5: Custom Fastener and Washer Assembly (Transportation)

Challenge: A vehicle component required a fastener system that resisted corrosion and vibration in marine-exposed environments.

Solution: We supplied proprietary fasteners assembled with phosphor-bronze washers and a specified plating system for maximal corrosion resistance.

Result: Long-term field performance improved, warranty claims were reduced, and the customer was able to market the component as marine-rated.

Process highlights

how projects move from concept to production

1. Discovery and requirements capture

We review drawings, functional needs, production volumes, and environmental constraints. Early discussion includes assembly methods and any regulatory or traceability needs.

2. Feasibility and DFM recommendations

Our engineers propose the most appropriate process (stamping, machining, or hybrid), material options, and preliminary tolerances that balance cost and performance.

3. Prototyping and validation

We produce prototypes for fit, function, and testing. Feedback is incorporated into tooling or machining programs.

4. Tooling and pilot runs

Tool & die development is followed by pilot production runs to validate tooling life and process stability.

5. Full production and continuous improvement

We transition to production with process controls, inspection plans, and regular reviews to identify opportunities for cost reduction and defect elimination.

Measurable impacts we deliver

Improved uptime: By supplying components that hold performance under stress, we help reduce field failures and line stoppages.

Lower total cost: Through DFM, consolidation, and optimized processes, customers see lower per-unit costs and simplified supply chains.

Faster time-to-market: Rapid prototyping and in-house toolmaking accelerate product launches.

Reduced inventory complexity: Kitting and part consolidation reduce logistics burden for customers.

Frequently asked questions (FAQs)

Can you provide references or full case studies?

Due to confidentiality agreements with some customers we provide anonymized case studies. We are happy to discuss analogous work and provide performance metrics relevant to your industry when appropriate.

Do you support regulatory or industry-specific testing?

We support documentation and part-level testing as specified by customers, and coordinate external testing labs or certifications when necessary.

How do you handle proprietary designs?

We maintain strict confidentiality and non-disclosure practices. Drawings and intellectual property are managed according to customer requirements.

Can you help reduce part costs on existing designs?

Yes. We perform value-engineering reviews to suggest material, process, or design changes that reduce cost while maintaining function.

Contact and project initiation

To review a potential project or request an example fitting your industry:

- Address: 2400 Farrell Road, Houston, Texas 77073

- Request a Quote: Send your drawings, volumes, and performance requirements. We will propose a phased plan: prototype, pilot, and production timelines.

Call (800) 875-3510 or Request a Quote to start a project review.